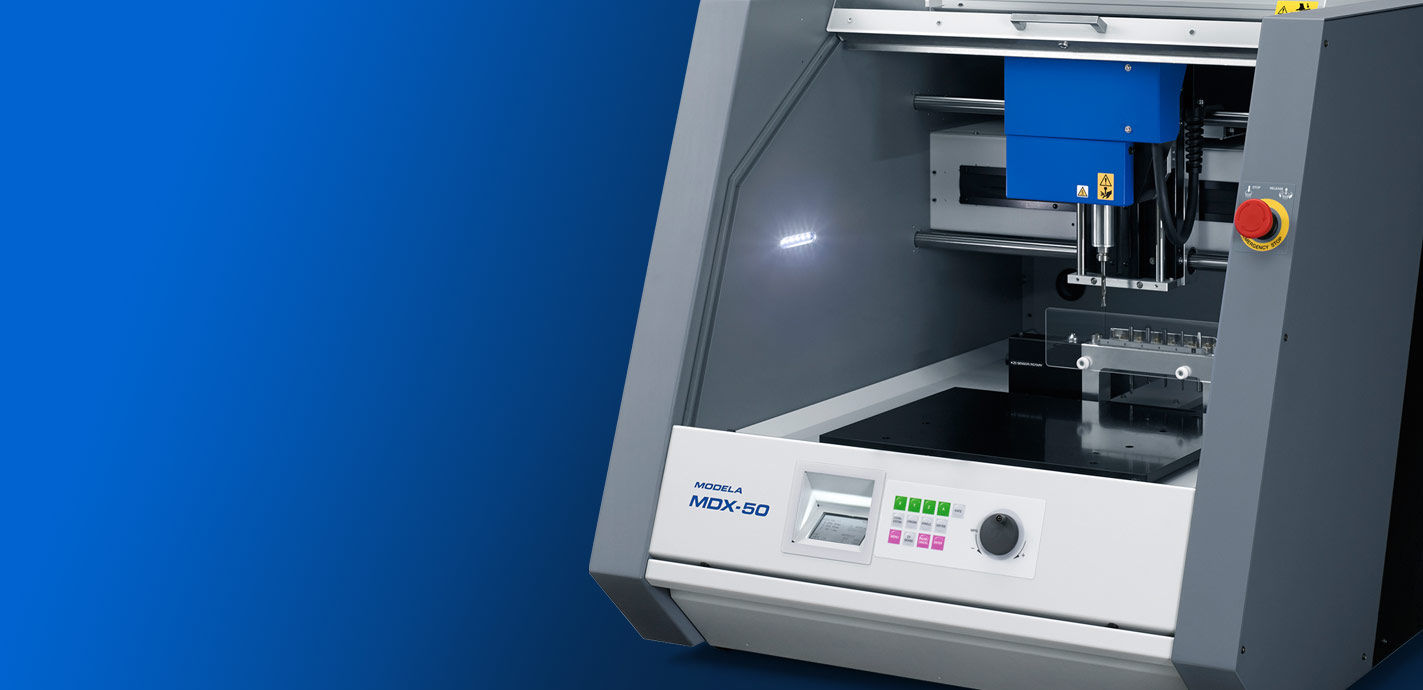

MDX-50 Benchtop Milling Machine

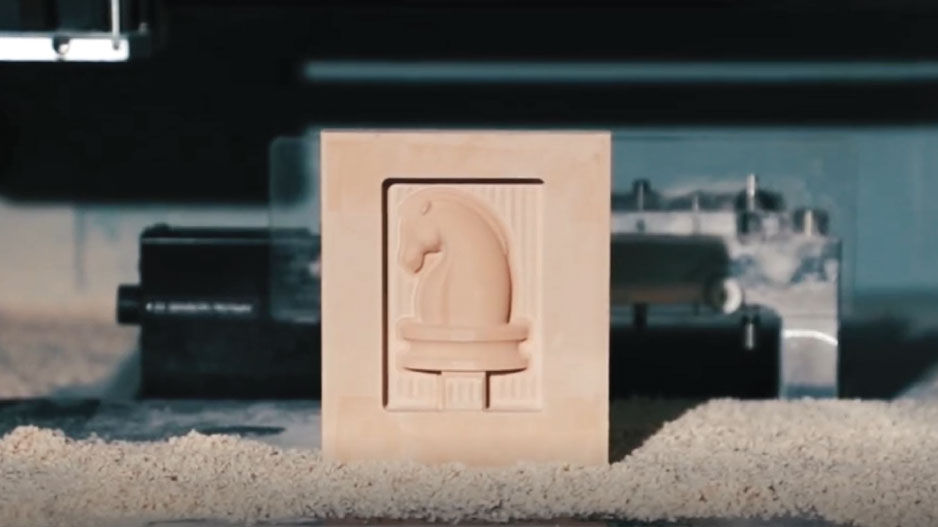

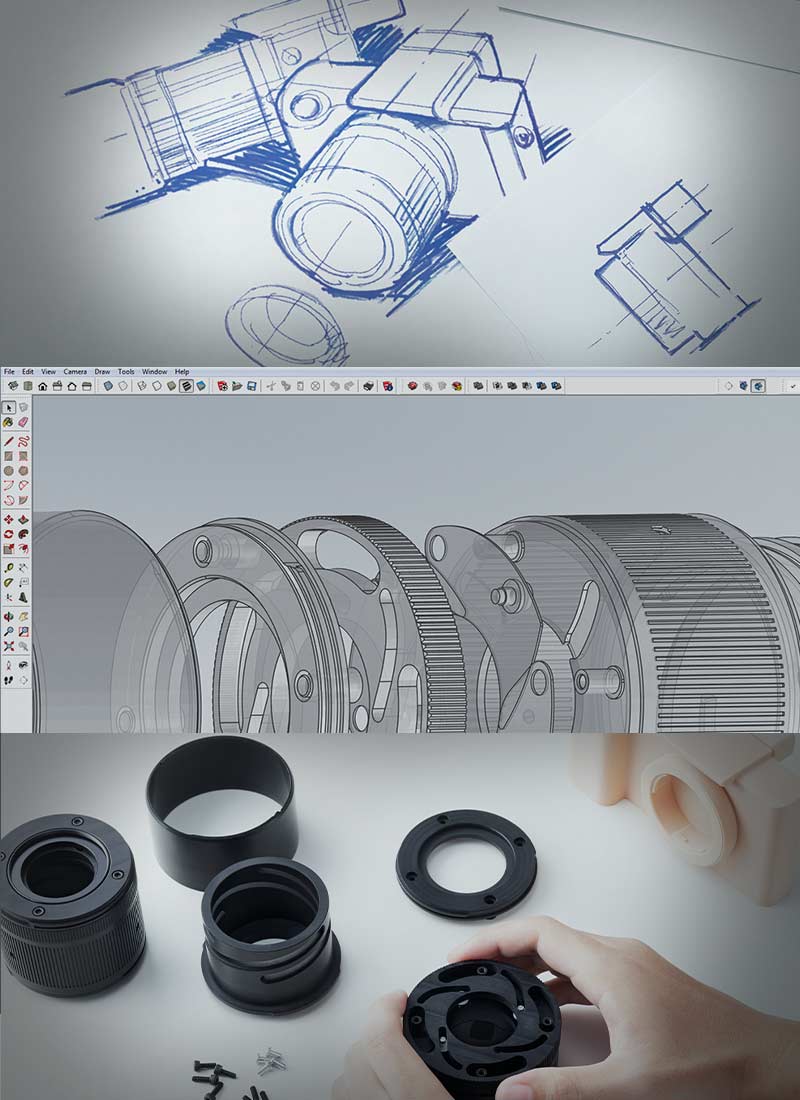

The MODELA MDX-50 combines precise, automated milling and unmatched ease-of-use. An ideal solution for short-runs and prototypes, the MDX-50 reduces operation time and simplifies production so users of all abilities can mill functional parts with incredible quality on a wide range of materials.

Other Distinguishing Features

- Advanced drive system supports dimensional stability

- Large machining area plus enhanced machine rigidity and drive mechanics

- Optional rotary axis rotates materials automatically from 0 to 360 degrees continuously or indexes for 2-sided, 4-sided and custom angles

- Simple-to-load tools and automatic machine calibration

- Requires no special electrical set-up and needs no additional air compressor

- Colour-coded LED status lights allow current job status to be monitored from a distance

- Built-in debris collection drawer with rail guided safety door for safe and clean production

- Ideal for use in studio and educational environments

Operator-Friendly Control and Software

Become a 3D milling expert almost immediately with the MDX-50’s simple yet powerful built-in control panel and virtual control panel (VPanel), and bundled SRP Player CAM software that’s easy-to-use and simplifies operation.

With the control panel at the front of the unit, almost all operations can be completed from the unit itself without having to go back to a PC. The VPanel interface operates seamlessly with the MDX-50 and allows users to make changes to spindle rotation or speed during operation.

Automatic Tool Changer

The MDX-50 increases performance with an expanded machining area and increased operating speeds, while reducing production time with faster job processing and a 5-station Automatic Tool Changer for continuous operation without stopping to change milling tools.

The MDX-50 increases performance with an expanded machining area and increased operating speeds, while reducing production time with faster job processing and a 5-station Automatic Tool Changer for continuous operation without stopping to change milling tools.