NEW PB-600, PB-400 Powder 3D Printer

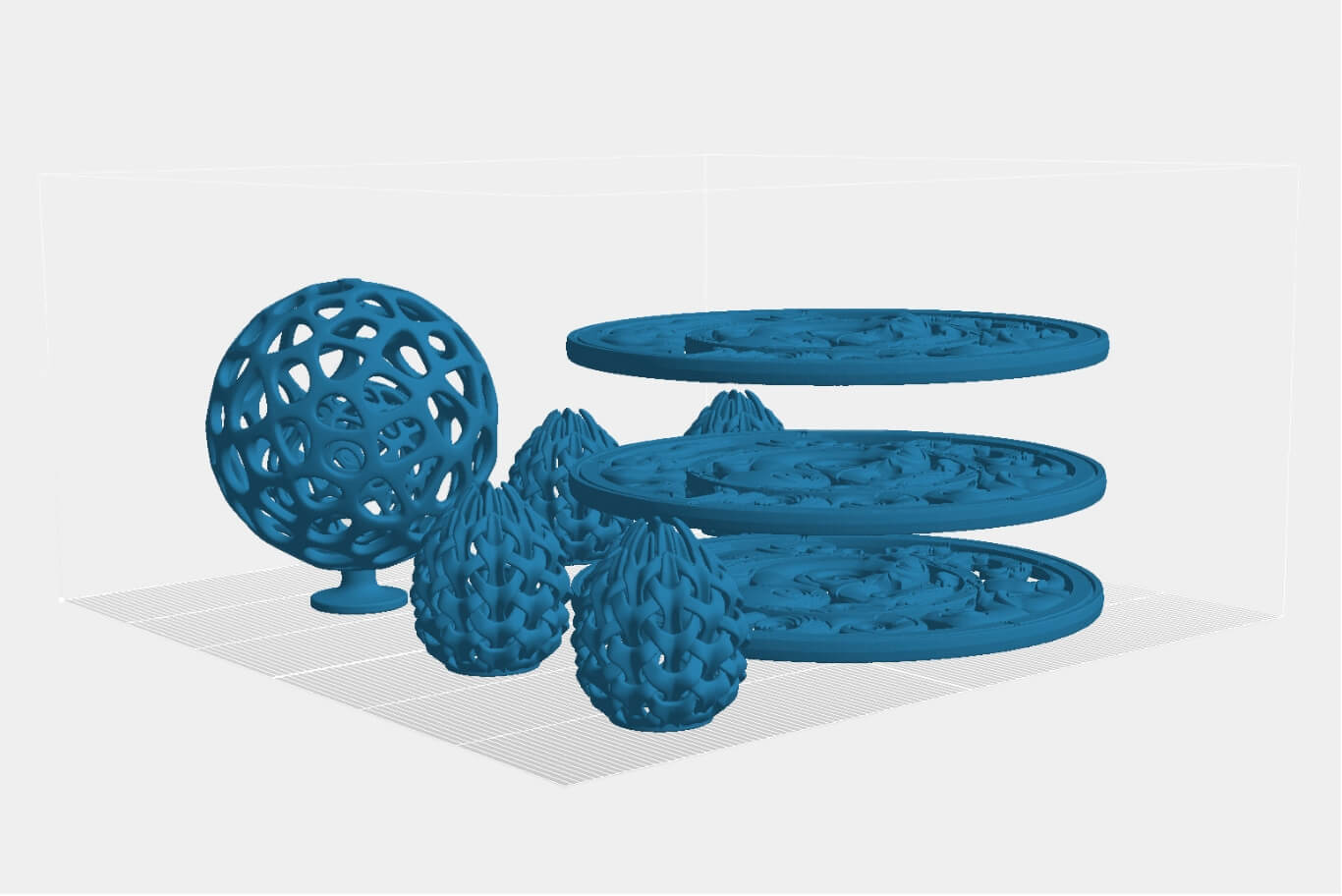

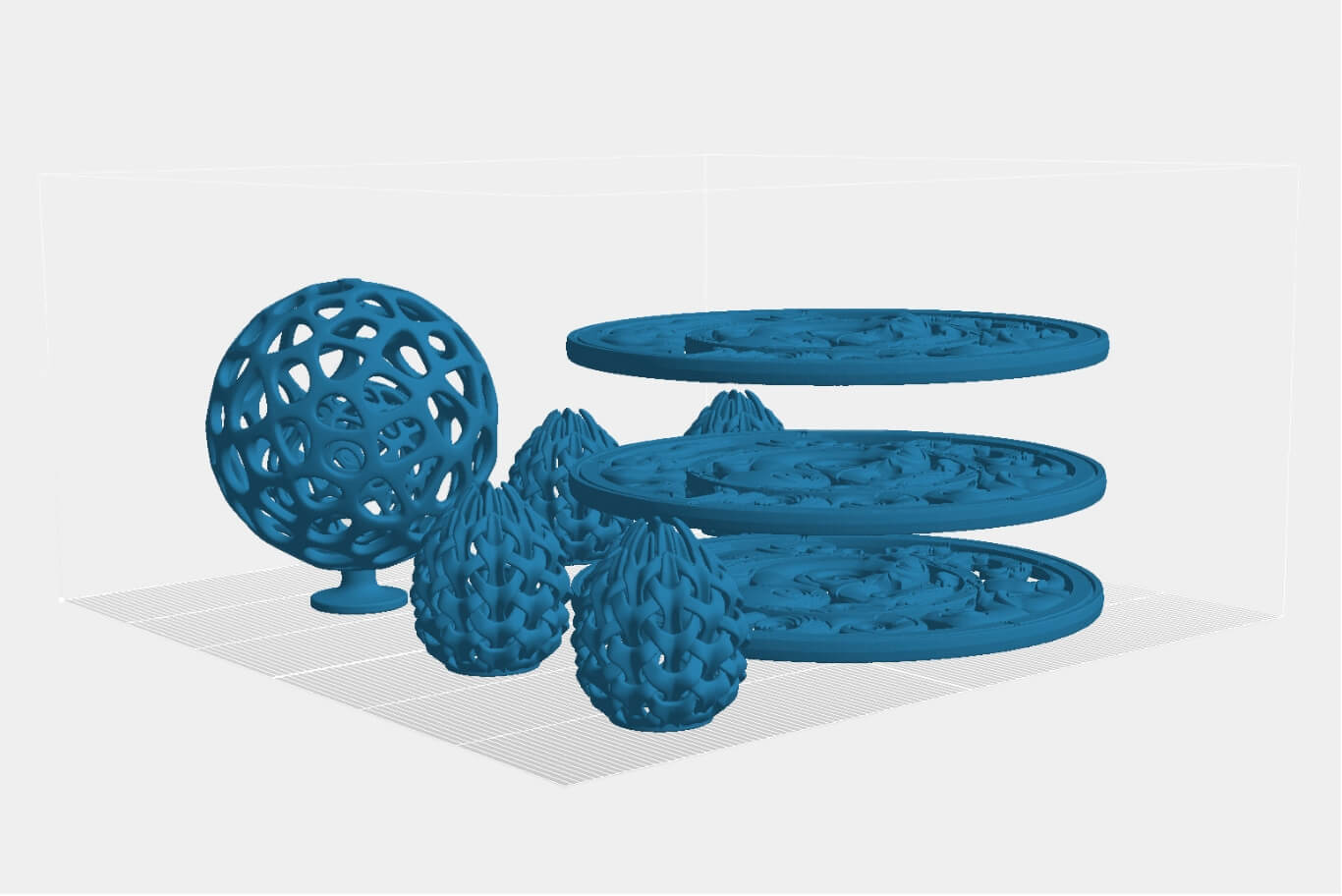

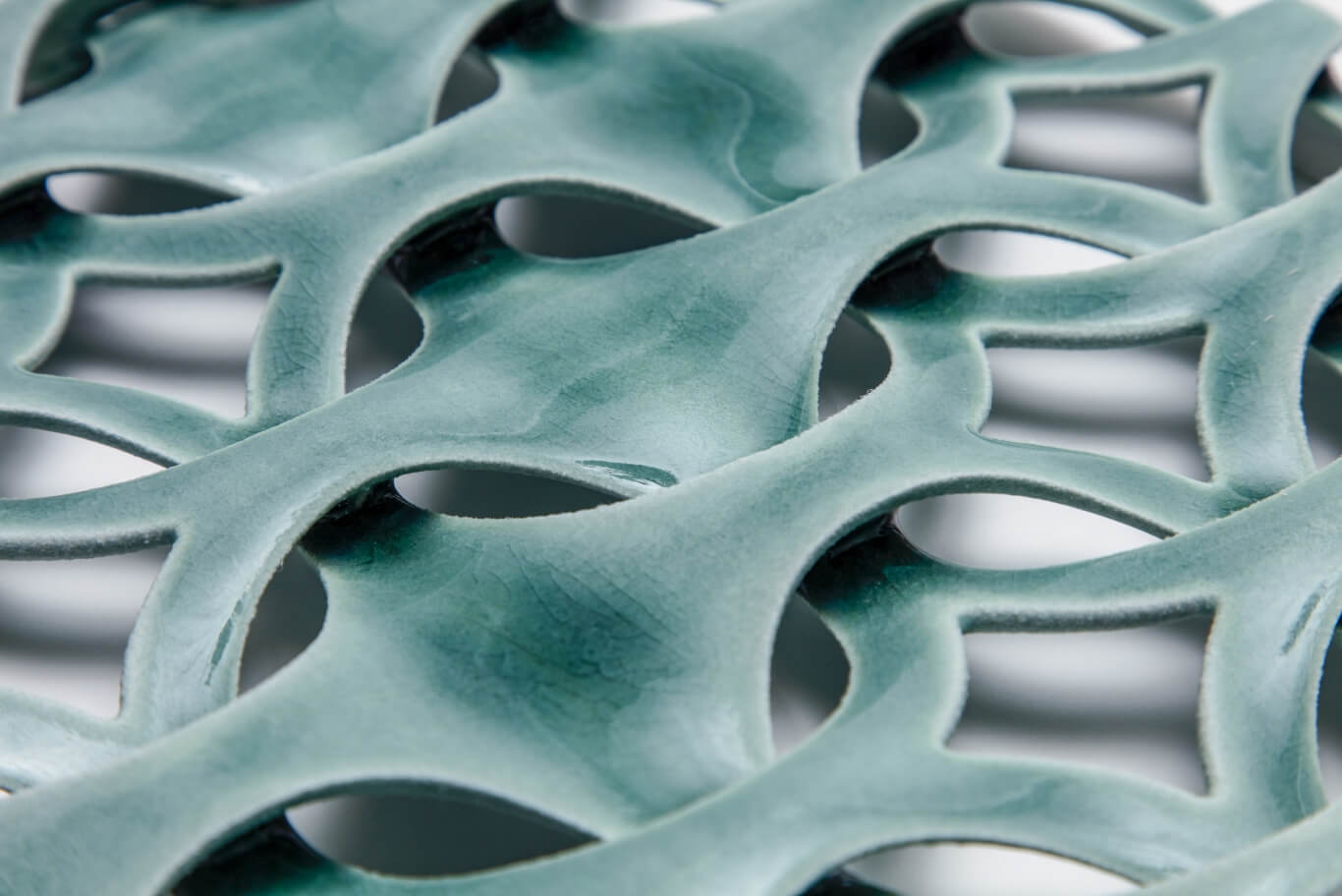

The PB-600/PB-400 binder jet Powder 3D Printer series produces creative and complex three-dimensional objects in high definition beautifully and efficiently. Its artistic and elaborate expressive power expands creative possibilities and brings innovation to the manufacturing process of ceramic products.

- Allows anyone to easily produce difficult shapes that could previously only be created by skilled craftsmen and complex models that cannot be manufactured by hand or milling machines.

- Available in two sizes for a wide variety of applications.

- High quality finish is achieved by using Brightorb, a special ceramic powder with fine particles.

Please note that this product is available only in certain regions and may not be sold in your area. Thank you for your understanding.

Value-added Applications Created by the PB Series

Creativity

The PB series is a binder jet type 3D printer that produces 3D objects by ejecting liquid binders from the print head and layering ceramic powder while fixing it layer by layer. It enables anyone to easily produce difficult shapes that could previously only be created by craftsmen, as well as complex models that cannot be manufactured by hand or with milling machines.

Productivity

The PB-600 has a maximum work size of 595 (W) x 600 (D) x 250 (H) mm, while the PB-400 has a maximum work size of 390 (W) x 290 (D) x 200 (H) mm. By laying out several different modeling objects, a large object or several smaller ones can be produced at once. Powder material remaining in the main unit after output can be reused for the next modeling task for low-cost operation.

Precision

Brightorb, a special ceramic powder, consists of fine particles to produce excellent performance with less than 1 % shrinkage during firing, which is essential for ceramic modeling. In addition, the PB series layers the fine material at the optimum thickness to create complex objects with high precision and a beautifully smooth finish.

Operation

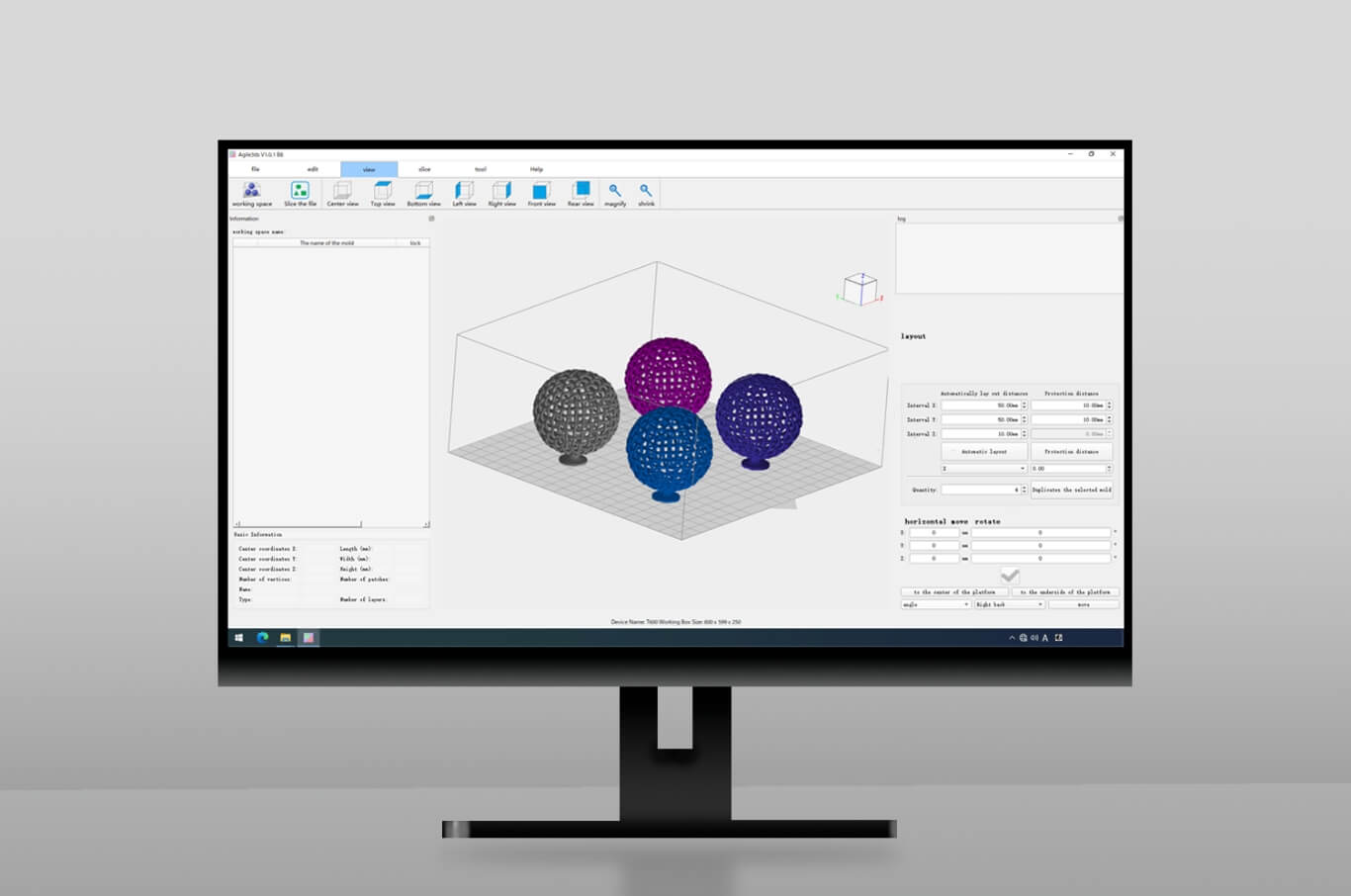

The printer includes slicing software that converts 3D data created with 3D CAD or 3D CG software into output data. It can also be operated intuitively from a monitor attached to the product itself, making it easy even for first-time users.

General workflow and main ancillary equipment

Software

3D CAD/3D software, such as Rhinoceros 3D

that can generate STL files.

Depowdering machine/facilities

Equipment that blows

off ceramic powder.

Dedicated room

For the Powder 3D Printer and powder

removal.

Vacuum Impregnation machine

Decompression equipment

to saturate impregnant.

Firing furnace

Firing furnace to solidify objects at

high temperature.

Dust collector

To collect powder materials from the

molding tank and remove dust from inside and outside the product.

PB-600

|

PB-400

|

|---|---|

|

BUILD SIZE

595 mm × 600 mm × 250 mm

|

BUILD SIZE

390 mm × 290 mm × 200 mm

|

|

Z AXIS RESOLUTION

0.1 mm

|

Z AXIS RESOLUTION

0.1 mm

|

|

BUILD SPEED

35 second/layer

|

BUILD SPEED

45 second/layer

|

Additional Information

Specifications

| PB-600 | PB-400 | ||

|---|---|---|---|

| Build Technology | Binder Jetting Method | ||

| XY Resolution (dots per inch) | 600 x 600 dpi | ||

| Layer Pitch | 0.1 mm (0.0039 in.) | ||

| Build Speed | 35 seconds/layer | 45 seconds/layer | |

| Build Size | Width | Max. 595 mm (23.4 in.) | Max. 390 mm (15.4 in.) |

| Depth | Max. 600 mm (23.6 in.) | Max. 290 mm (11.4 in.) | |

| Height | Max. 250 mm (9.8 in.) | Max. 200 mm (7.9 in.) | |

| Powder Materials | Ceramic Powder | ||

| Binder | Water-Based Liquid Binder | ||

| Environment | During operation |

Temperature: 20°C to 24°C (68°F to 75.2°F) Humidity: Max. 50 % RH (no condensation) 20°C (68°F), and small temperature changes are recommended |

|

|

Not Operating *1 |

Temperature: 5°C to 40°C (41°F to 104°F) Humidity: 20 % RH to 80 % RH (no condensation) |

||

|

Distance Accuracy (with correction) |

Error of less than ±0.3 % of distance travelled or ±0.5 mm (0.0196 in.), whichever is greater | ||

|

Dimensions (Width x Depth x Height) |

3,150 mm × 1,344 mm × 1,900 mm (124.0 in. × 52.9 in.

× 74.8 in.) excluding PC arm stand |

1,709 mm × 970 mm × 1,382 mm (67.3 in. × 38.2 in.

× 54.4 in.) excluding PC arm stand |

|

| Weight | 1,200 kg (2,645 lb.) | 430 kg (947 lb.) | |

| Power Supply | AC 230 V Single Phase 16 A | ||

| Included items | User’s Manual, Slice Software, PC for Printer Control Software and Monitor, etc. | ||

*1: The condition during operation is applied when powder is filled.

| System requirements for Slice Software | |

|---|---|

| Operating system | Windows 10/11 |

| Processor | Core i5 Generation 8 or more |

| Memory (RAM) | 8 GB or more |

| Video card and monitor | NVIDIA GeforceRTX 3060 or more (Pro graphics card not supported) |

Brochure

Download Your PB-600/400 Brochure

Get your digital guide to all the features, applications, benefits and specifications of the Powder 3D Printer.