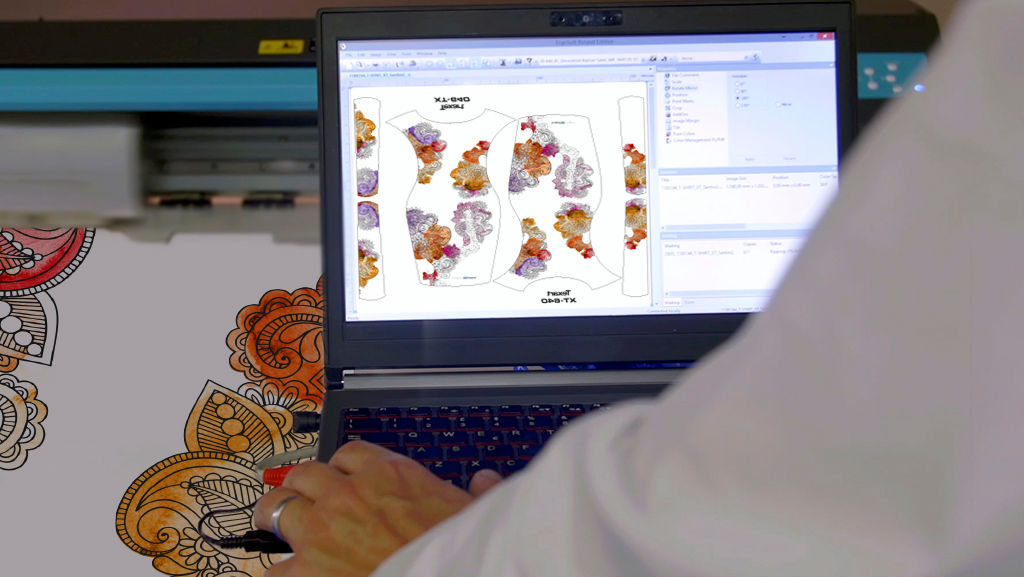

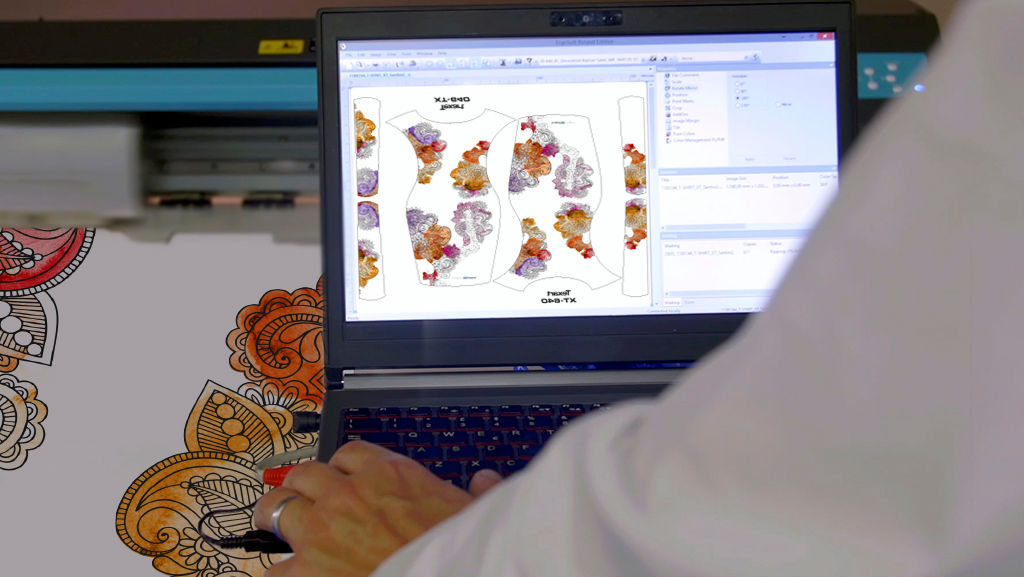

Roland DG Products for Fashion Apparel

Digital dye-sublimation transfer is increasingly used by high-end fashion brands for short-run and limited edition production. If you are currently using analogue methods to produce fabric for fashion and other textile applications, Roland DG’s digital textile print technology offers the significant benefits of flexibility, cost and time efficiency.

Low Fixed Costs

Whether you’re printing a single garment or 500 linear metres of fabric, with digital dye-sublimation the set up costs are the same, and they’re low. It’s easy to predict costs and offer a competitive price, no matter how small the run.

Efficient production

Dye-sublimation transfer print production offers significantly reduced set up times compared to traditional methods of production so it’s quick and easy to do one-offs, sampling or limited editions. For fast responses to customer demands and the ability to offer quick turnaround production.

With digital dye-sublimation transfer printing the process is extremely streamlined – you simply print and press and the garment is ready to be sewn – no complicated fixing processes.

Flexibility of output

Choice of Fabrics

Polyester is typically used in digital dye-sublimation transfer printing, but you’re not limited to 100% polyester. There are incredible fabrics to choose from which feel far from synthetic, including glossy satins for blouses, dresses and ties and durable, thick canvases for items such as bags, belts and luggage.