Roland DG technology allows professional skills to be applied to a personal hobby

Dave Tilbury

Following an extensive search for a machine that produces designs so intricate they are almost impossible to do by hand, designer Dave Tilbury chose the monoFab SRM-20.

Dave Tilbury was made redundant after a lifetime of working in the engineering sector and was keen to start a new phase in his career within the creative industry. After graduating from a degree in Ceramics, the former motorsport engineer first came across Roland DG whilst working for a London-based design company, in which he utilized the Modela MDX-40A milling machine to support model making work that had, up until 2010, been predominately carried out by hand.

Working with the robust machine on a daily basis, Dave quickly got to grips with the capable engineering behind the technology and recognized the MDX-40's ability to produce high a precision and cost-effective solution to his cutting needs. With a personal interest in manufacturing model aircrafts, the 55-year-old explored the possibility of investing in a Roland DG machine to use in his own time.

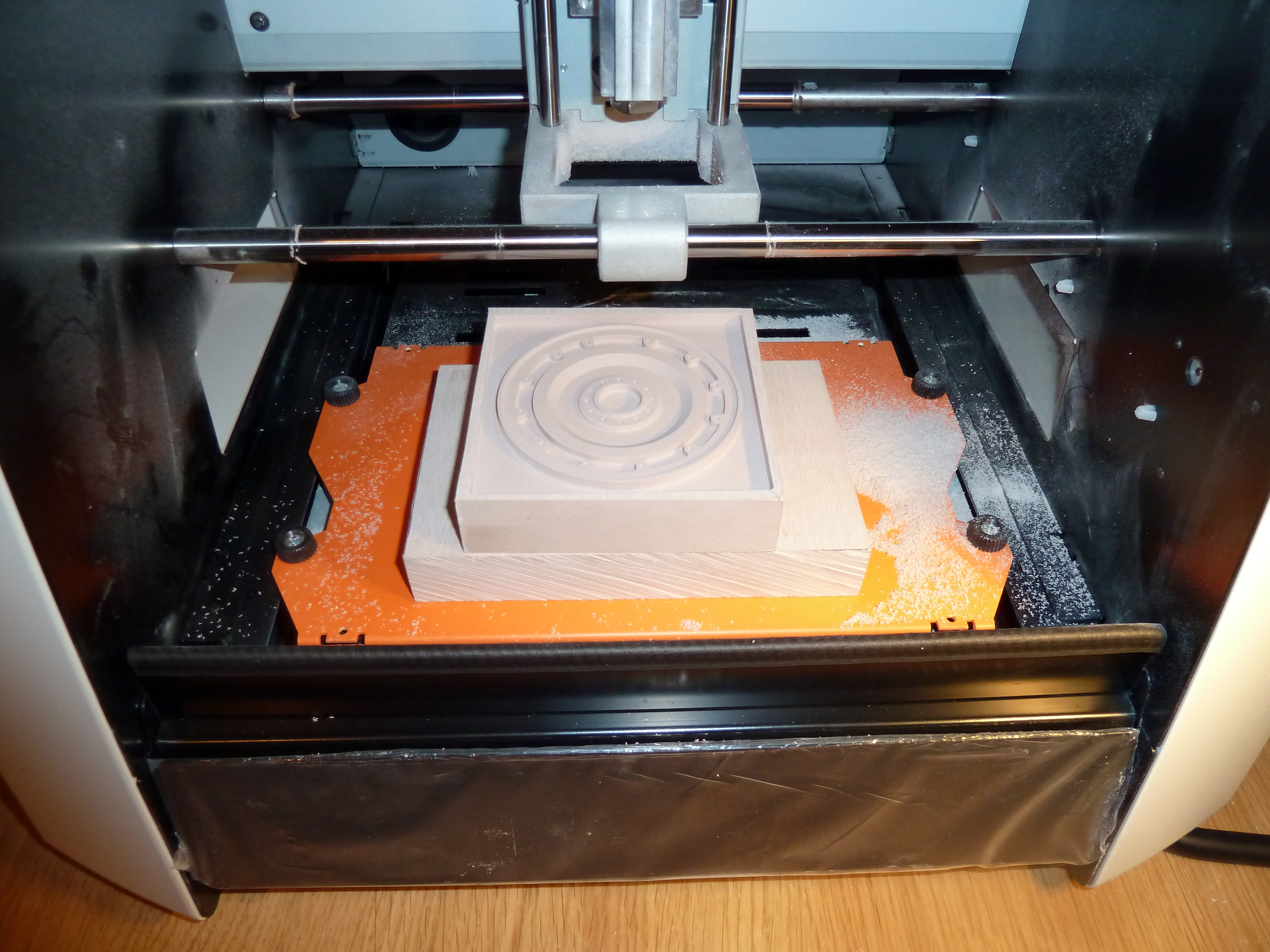

Despite the MDX-40 proving to be a highly versatile piece of equipment that could be utilized beyond the business environment, Dave wanted a machine that was more compact so not to impact on his limited space at home. As the leading manufacturer of print, cutting, engraving and 3D milling technology, Dave was confident Roland DG's latest 3D desktop milling machine, the monoFab SRM-20, would be the perfect compact solution for his cutting needs.

Discussing the transition from a professional to personal Roland DG user, Dave said: "Seeing the results of the MDX-40 in conjunction with using 3D CAD, I knew it would only be a matter of time before I took this direction for my modelling at home. However, I needed something smaller and so when the desktop version arrived in the form of the SRM-20, it was the perfect match. Not only did I have a more compact machine, I also did not need to compromise on the quality, precision and reliability that I had come to expect from a Roland DG milling machine."

Despite the fact the SRM-20 was smaller than the MDX-40, its innovative subtractive rapid prototyping (SRP) ensures a precise and smooth finish, including smooth curved surfaces and intricate details, which allowed Dave to create the molds for his model aircrafts.

The SRM-20 can mill a variety of materials with a wide range of shapes and sizes to create intricate details and high quality finishes, perfectly placed to create the molds for Dave's model aircrafts. The latest generation desktop machine boats innovative subtractive rapid prototyping features to deliver accuracy and efficiency in a compact format to allow Dave to produce products that would be too difficult to make by hand.

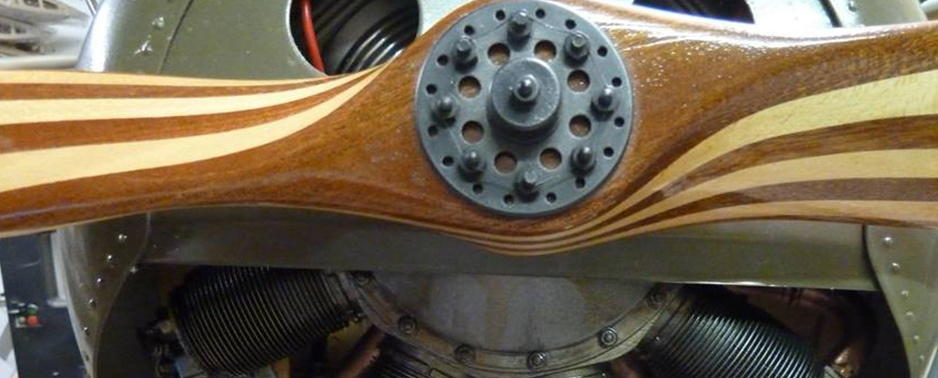

"Since buying the SRM-20 I have worked on numerous small projects, including dummy scale engines, fuel filler caps and tail wheel hubs; which this machine is perfect for. Complex in their geometry, they would be extremely difficult to make by hand," he added.

Dave is now using his SRM-20 to craft elements for his aircraft models twice a week, while also still using the larger MDX-40 at work. Speaking about how the SRM-20 has allowed him to apply his professional skills to his personal hobby, Dave said: "Now I have gained some experience with the SRM-20, I am very excited to see what the future holds. The application of this process for my model making is truly boundless."